F-2 Machine Tapes

Main Industry Segments

Paper Manufacturing and Processing, Paper Printing and Finishing

Applications

Machine Tape, Paper Handling Belt, Power Transmission Belt, Processing Belt

Special Features

Abrasion Resistance, Constant and Gentle Positive Grip, Constant Coefficient of Friction, Forgiving in case of short term shock like overloads, Outstanding Flex-Fatigue, Versatile

Product Construction / Design

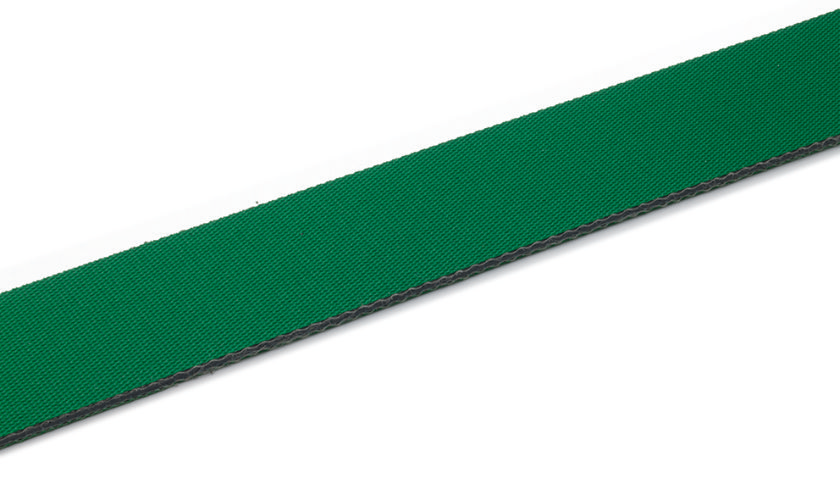

Conveying Side Material |

Acrylonitrile-Butadiene-Rubber (NBR) |

Conveying Side Surface |

Rough Surface |

Conveying Side Property |

Adhesive |

Conveying Side Color |

Green |

Traction Layer (material) |

Polyamide (PA) |

Number of Fabrics |

2 |

Pulley Side Material |

Acrylonitrile-Butadiene-Rubber (NBR) |

Pulley Side Surface |

Impregnated Fabric |

Pulley Side Property |

Non-Adhesive |

Pulley Side Color |

Green |

Product Characteristics

Antistatically Equipped |

Yes |

Adhesive Free Joining Method |

No |

Food Suitablilty, EU Conformance |

No |

Food Suitablilty, FDA Conformance |

No |

Technical Data

Thickness of Belt |

1.8 mm |

0.07 Inch |

Mass of Belt (belt weight) |

1.8 kg/m |

0.358 lb/sqft |

Tensile Force for 1% Elongation (k1% Static) per Unit of Width (Habasit Standard SOP3-155 / EN ISO 21181) |

14 N/mm |

80 lbf/in |

Tensile Force for 1% elongation after Relaxation (k1% relaxed) per unit of width (Habasit Standard SOP3-155 / EN ISO 21181) |

4.4 N/mm |

25 lbf/in |

Min. Operating Temperature Admissible (continuous) |

-20 C |

-4 F |

Max. Operating Temperature Admissible (continuous) |

100 C |

212 F |

Seamless Manufacturing Width |

1200 mm |

47.24 Inch |

All data are approximate values under standard climatic conditions: 23 C/73 F, 50% relative humidity (DIN 50005/ISO 554)

Joining Related Properties

Joining Method |

Thermofix 75 |

link to Chemical resistance information: https://rims.habasit.com

Pulley Diameter (minimum) |

mm/inch |

60/2.36 |

Pulley Diameter Minimum with Counter Flection |

mm/inch |

60/2.36 |

Slider Bed Suitable |

Value |

Yes |

Carrying Rollers Suitable |

Yes |

|

Troughed Installation Suitable |

No |

Chemical Resistance

Link to 'Chemical Resistance Information

Mode of Use or Conveyance

Declined, Horizontal, Inclined, Twists, Twists with short center distance, Vertical

Calculations

For most applications calculation is not required. Should you still need a calculation: please ask MIB

Recommendation

Do not go below initial elongation (epsilon) - 0.5%, Install the slack belt and tension until running perfectly under the full belt load.

Protect belts from sunlight/UV-radiation/dust and dirt. Store spare belts in a cool and dry place and if possible in their original packaging.

Protect belts from sunlight/UV-radiation/dust and dirt. Store spare belts in a cool and dry place and if possible in their original packaging.